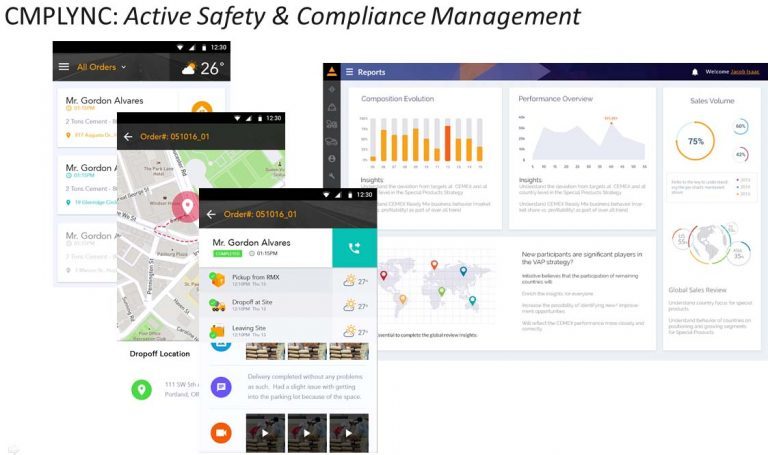

The just-released Surface Tech digital platform, which empowers concrete manufacturers and contractors with interconnectivity, incorporates three major modules: CMPLYNC™ (mobile app for compliance and safety), TRKR™ (e-commerce) and ASMBL™ (e-content). In this article, we’ll provide an overview of CMPLYNC, a solution that actively manages compliance and safety issues.

CMPLYNC is a mobile application built to address and streamline compliance and safety issues. The app improves job site and transportation safety and mitigates the risk of construction defect claims.

Safety

With CMPLYNC, the driver must go through a safety checklist before completing a delivery. Pre-programmed mileposts for safety requirements are clicked off for documentation. Driver also has the ability to record video, photos and notes to further document the job site experience. Weather data is captured automatically at start, site arrival and completion of delivery. Tracking of the load from plant to site is also a geo-recorded documentation fed to the backroom platform.

CMPLYNC ensures that the driver records are up to date. All of the required details such as driver’s licenses and required eligibility stats are kept up. If a contractor, all licensing is also kept up to date. The data is synced into the platform, allowing verification via the digital platform rather than by device alone.

CMPLYNC ensures that the driver records are up to date. All of the required details such as driver’s licenses and required eligibility stats are kept up. If a contractor, all licensing is also kept up to date. The data is synced into the platform, allowing verification via the digital platform rather than by device alone.

Construction Defects

CMPLNC allows the capture of any notable issues from plant to site delivery and the actual pour. By having this important information documented, the supplier and contractor will have a more robust defense should a claim be made in the future.

Scenario One

Although the Surface Tech software program has predicted the concrete strength needed on a project and specified the recipe used to make the concrete, when the driver delivers the product to the site, the contractor asks that more water be added. This changes the consistency and creates a different performance level than planned, diminishing the product’s strength. Documentation is necessary, not simply accommodation.

Scenario Two

The driver delivers the product to the site, but the weather conditions are not good for pouring. However, pouring is ordered. To back up the auto-weather feeds, the driver takes photographs and videos on site and records notes, capturing the situation and delivering to the platform. This real-time data is instantly shared with the supplier via the program.

Contact Us for more details on the entire platform and its modules.