For years, contractors have utilized several common types of supplemental cementitious materials (SCM), including fly ash, slag cement, calcined clays, and silica fume to partially replace traditional Portland cement in concrete mixes. The use of these materials has been supported by significant research and testing, as well as long-term performance monitoring.

Now the same rigorous testing procedures are being applied to JUNO XP, Surface Tech’s alternative supplemental cementious material (ASCM), and the reports from Stage 4 testing show JUNO XP produced “fantastic results,” according to Jon Belkowitz, PhD, chief technology officer for cement.

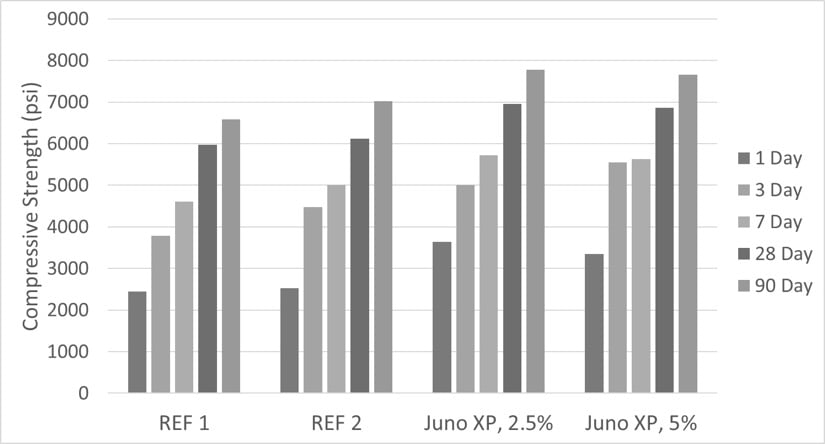

“The 90-day strength test results show JUNO XP is awesome! Throughout the 90-day set of results, the strength and durability of the JUNO XP-enhanced concrete proved out above the 1709 ASTM references.”

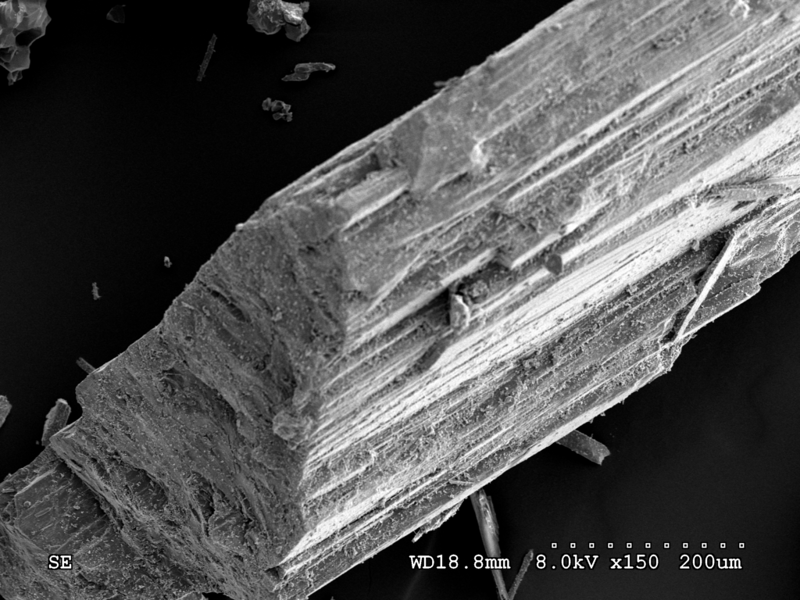

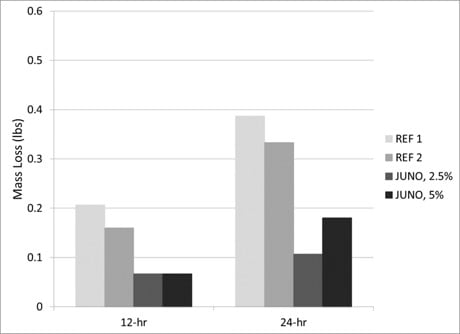

The innovative technology behind JUNO XP generates a hardened matrix that increases cementitious efficiency (see Compress Strength graph), and the resistance to physical attack (see Underwater abrasion graph).

Testing on JUNO XP covers a one-year time period, and by achieving excellent results at the 90-day milestone, the product will now enter the field-testing phase.

Standards for the evaluation of materials for 1709 ASTM certification can be found at https://www.astm.org/Standards/C1709.htm