Field test on residential mix paves the way for improved cold weather resistance

Ready-mix providers throughout Colorado face daunting challenges when creating residential concrete placements. Damage caused by freeze-thaw cycles, de-icing salts and excessive use can spell big trouble if the concrete fails to hold up under Colorado’s brutal winters. Homeowners generally hold concrete providers responsible if slabs, driveways, sidewalks and other residential placements don’t last through the first winter without change from shrinkage, cracking or surface deterioration.

JUNO XP’s reputation for increasing toughness and durability convinced one Colorado ready-mix provider to put it to a test. The residential mix specifications, shown in Table 1, required a designed compressive strength of 4,000 psi and 4.5 to 6.5 percent entrained air for freeze-thaw mitigation. It also needed to achieve a slump of four to six inches.

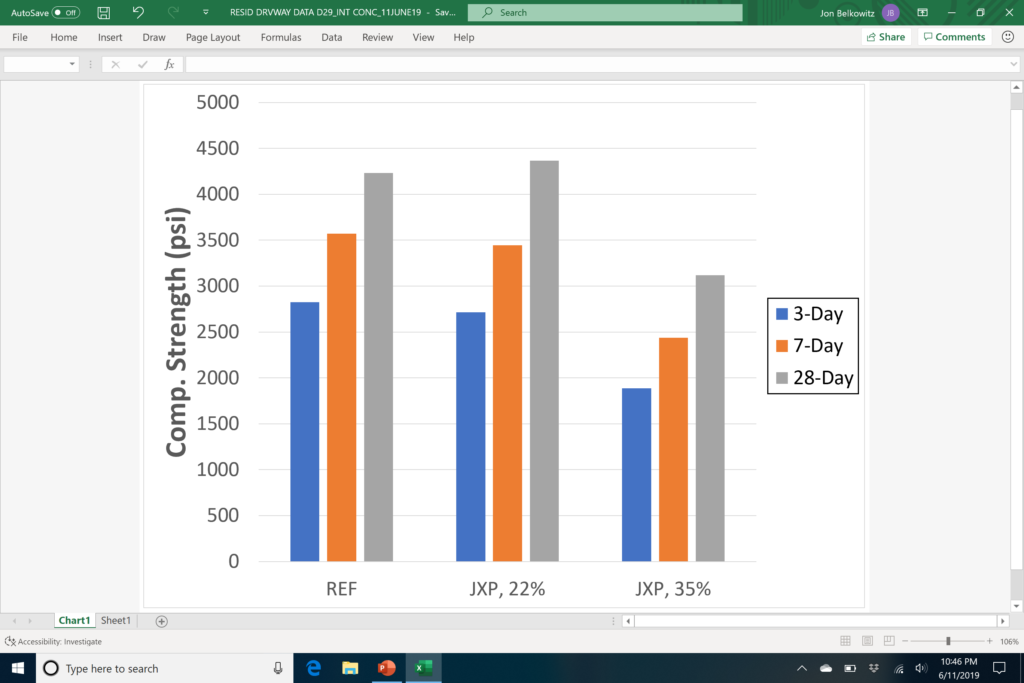

Table 2 details the fresh properties of the mix. Preliminary results show that JUNO XP maintained strength as well as slump and air entrainment properties, even though it reduced the amount of traditional cement in the mix. Moreover, JUNO XP also reduced the ready-mix provider’s cost for the mix, while still meeting specifications for compressive strength of C39 -3, -7, for 28-days. (See Figure 2 for Comparative Strengths.)

“With JUNO XP, we succeeded in setting up a concrete surface that we believe will maintain durability against freeze-thaw and de-icing salt attack,” said Jon Belkowitz, Surface Tech’s chief technical officer for concrete. “JUNO XP also delivered an enhanced concrete finish and improved roadside appeal.” (See Figures 1 and 4 for photo results of shrinkage and moisture loss on the test slabs.)

JUNO XP is an alternative supplementary cementitious material (ASCM) developed by Surface Tech to increase the toughness and durability of concrete, making it stronger and last longer. The Colorado residential test will continue to be monitored over the coming year. Find more information about JUNO XP here.

Table 1 – Concrete Mix Designs Evaluated

|

Materials

|

3000, EXT, FLT WORK | |||

| REF | JUNO XP RPL 22% | JUNO XP RPL 35% | ||

| Lb Per C. Yard

|

HOLCIM Type I-II | 432 | 329 | 300 |

| Fly Ash F | 108 | 115 | 101 | |

| Juno XP | 0 | 10 | 17 | |

| LGE # 57 / 67 | 1351 | 1377 | 1390 | |

| LGE #8 | 322 | 348 | 361 | |

| Concrete Sand | 1366 | 1392 | 1405 | |

| Water | 245 | 240 | 238 | |

| (gal Per C. Yard) | (29) | (29) | (28) | |

| Fl Oz Per C. Yard | AEA | 2.7 | 2.3 | 2.1 |

| HRWR | 22 | 18 | 16 | |

Table 2 – Concrete Fresh Properties

|

Materials |

4000, EXT, FLT WORK | ||

| REF | JUNO XP RPL 22% | JUNO XP RPL 35% | |

| Unit Weight (pcf) | 140.2 | 139.8 | 135.6 |

| Air Content (%) | 5.1% | 5.2% | 6.0% |

| Slump (inches) | 4.25 | 4.50 | 4.25 |