Six years out — the fiber-reinforced roadway dramatically reduced cracking

If your next asphalt pavement mix could reduce cracking by 50 percent or more compared to your current mix, would you be interested in trying it? In 2015, the Kentucky Transportation Cabinet (KYTC) decided to do just that. They put a PG76-22 mix reinforced with ACE XP Polymer Fibers® to a real-world test against a PG76-22 control mix without reinforcement.

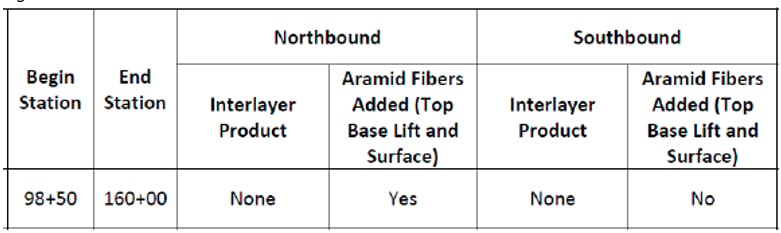

Both mixes were placed over a 7-inch jointed, concrete pavement. The northbound and southbound lanes were divided into four sections:

The northbound lane contained ACE XP fiber reinforced overlay in all layers. The southbound lane of Section 1 served as a control of the normal treatment of unreinforced PG 76-22 mix.

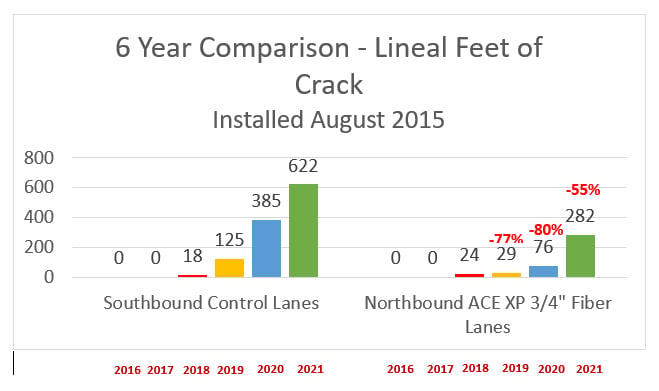

Both the northbound and southbound lanes were placed in the same year to allow for a proper comparison. Manual crack counts, recorded in 2018, 2019, 2020 and 2021, were performed on the ACE XP reinforced section (Northbound) and control section (Southbound). Equal-length ACE XP and Control sections of 3500’ were measured annually and all transverse cracking (of any type) was documented.

As promised, ACE XP Polymer Fibers® reduced cracking, compared to the control pavement sections showing improved transverse (all types) cracking resistance of 77%, 80% and 55% in years 4, 5 and 6.

For more details on the KYTC Dixie Highway test, contact Phil Blankenship at BATT Asphalt Tech & Training (phil@blankenshipasphalttech.com) To learn how you can put ACE XP to work reducing cracks and expanding the life of your next paving project, visit https://surface-tech.com/pilot-program-acexp/

Learn more about the history of this project here: https://surface-tech.com/portfolio/cs-hall-paving-kytc-dixie-hwy-us-31w/