PRESS RELEASE

LA JOLLA – REARM HR, a product from Surface Tech, LLC allows higher Reclaimed Asphalt Pavement (RAP) asphalt concrete mix designs to meet performance requirements while lowering costs.

RAP, a recycled product used in hot mix asphalt, typically has to be used in lower concentrations than the dosages available with REARM HR in order to meet performance specifications.

Surface Tech’s REARM HR uses their ACE XP Polymer Fiber™ and includes TUFFTREK 4007 from Georgia-Pacific Chemicals. By varying the dosage of each product, field tests and lab studies indicate high RAP mix designs with these products can provide equal to, or enhanced cracking and rutting performance compared to that of lower RAP mixes. These high RAP designs reduce the amount of virgin binder and virgin aggregate needed, resulting in lower costs.

ACE XP Polymer Fiber™ is used to reinforce the resulting combined binder with 10 to 20 million individual high strength 38mm aramid fibers, depending on dosage. TUFFTREK 4007 is used to soften the virgin binder’s PG which compensates for the additional aged RAP binder.

“This is a SMART choice for asphalt producers,” says Joe Dennis, VP & Chief Technical Officer at Surface Tech. “TUFFTREK 4007 and ACE XP Polymer Fiber™ are introduced at the plant during production. This puts the control with the plant and allows for the HIGH RAP mixes to be started and stopped as necessary to accommodate other manufacturing needs.”

“We are excited that Surface Tech is able to use our product for this innovative asphalt additive that has the potential to reshape the way we think about high-RAP mixes in road construction,” says Ryan Lynch, Senior Commercial Development Manager at Georgia-Pacific Chemicals.

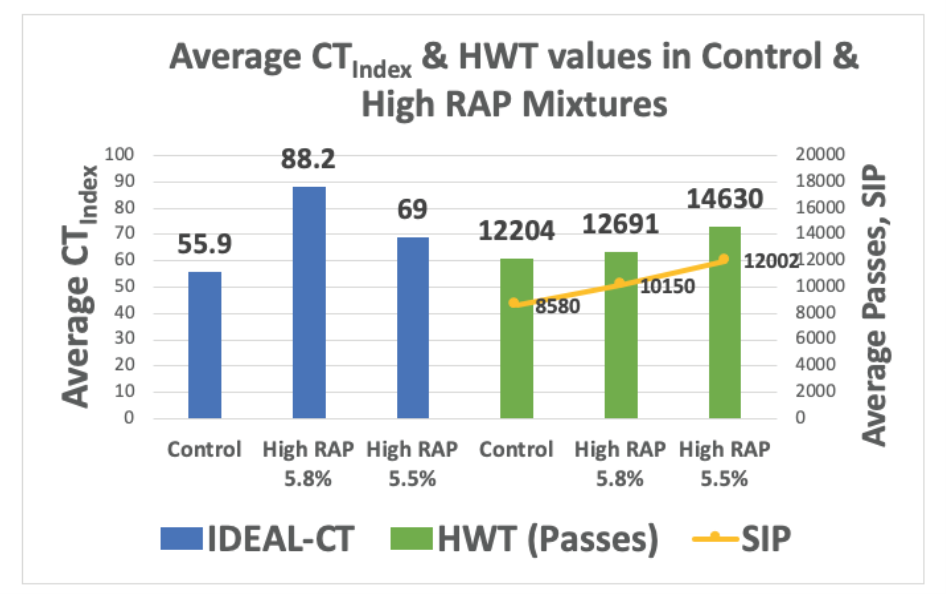

Fig 1 – IDEAL CT and Hamburg Wheel Tracker Data for Control Mix with 5.6% PG 64-22 Virgin Binder and 20% RAP. High Rap Mix with 36% RAP, TUFFTREK 4007 & 38mm ACE XP Polymer Fiber. Testing Performed by Blankenship Asphalt Tech & Training.